Selecting the right battery pack OEM partner is one of the most critical decisions for any company that relies on dependable power systems. The right partner ensures quality, safety, and consistent supply, while the wrong one can cause delays, cost overruns, and product failures. A battery pack OEM provides customised energy storage solutions for various industries, including electric mobility, smart devices, healthcare, and industrial automation. This guide explains what to look for when choosing an OEM partner, how to evaluate them, and why working with experienced providers offering one-stop solutions can save both time and money.

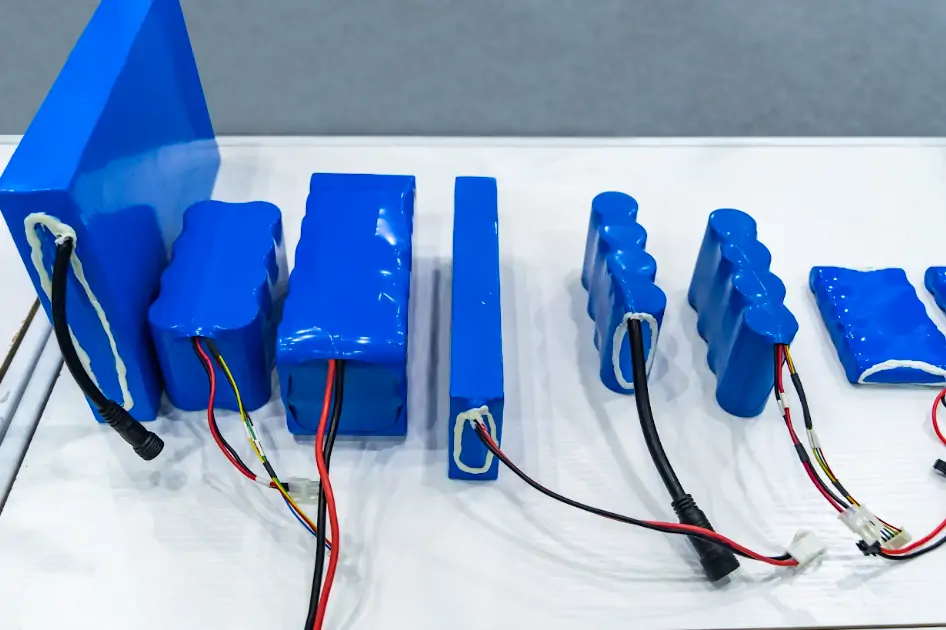

The Battery Pack OEM (Original Equipment Manufacturer) is responsible for assembling and manufacturing battery packs based on client specifications. These battery cells and packs may contain lithium ions, iron lithium phosphate (LiFePO4), and other chemical compositions depending on the application. A proven battery pack OEM will guarantee that the pack performs as required, is safe and sized correctly. Through maintaining the work with reputable battery pack manufacturers, one will be able to minimize the possibilities of poor quality of the battery packs, the use of untested materials, and inconsistent performance. Great OEM partners are also able to create new custom battery packs to fit your specific needs in terms of power and design.

Careful evaluation is required to select an OEM partner. The most essential elements of choosing a battery pack OEM are:

OEMs of specialized battery packs are qualified to the ISO9001 (quality control), ISO14001 (environmental management) or ISO45001 (occupational safety and health). Global markets also need to comply with CE, UL, UN38.3 and RoHS. Certified OEMs have stringent quality control measures in place to ensure safety and reliability. Many partners who provide one-stop solutions meet multiple certification criteria to manage all processes in-house.

Request a visit to the production facility or provide a photo. A reliable battery pack OEM utilises a clean room, an automatic assembly line, and advanced testing equipment. When battery pack manufacturers provide one-stop solutions, they are likely to operate integrated production systems, thereby minimising the need for outsourcing.

Competent battery packs OEMs rely on skilled engineers, designers and assembly workers. They understand the relationship between cell chemistry, battery management systems (BMS) and mechanical housing. OEMs which offer one-stop solutions usually have mechanical design, electrical testing and safety verified teams in-house.

The experience of battery pack OEMs will go a long way in ensuring consistency in performance. Get a company that has a clear track record of offering services in the fields of medical, industrial, automotive, etc. Case studies can be checked, and customer referrals requested to confirm results. A long-established battery pack manufacturer that offers one-stop solutions typically has a solid track record and established customer trust.

There are significant advantages to working with OEMs that offer one-stop solutions compared to trading with multiple vendors.

Here's why this approach is so good:

Successful partnerships depend on open and transparent communication. Excellent battery pack OEMs respond quickly and aggressively. Respond promptly to inquiries, share progress updates, and report any issues promptly. After-sales service also defines a trusted partner. Battery pack manufacturers should provide support for troubleshooting, document delivery and warranty billing.

The cost is a factor at all times, but the most affordable does not necessarily mean the best. Battery pack OEMs that are low-cost could skip materials and tests, which can lead to failure later. Instead, focus on the value that matches the price. Review the quotation and verify for additional services, including testing, packaging, and certification. OEMs that provide one-stop solutions typically include these processes with transparency.

Once the OEM of the battery pack is chosen, a good partnership will be a guarantee of quality and innovation.

Specific steps:

Long-term relationships with battery pack manufacturers that offer one-stop solutions facilitate development, enable rapid adjustments, and lead to performance improvements over time.

When selecting a battery pack OEM, including exterior design, protection housing, and assembly accuracy, are equally important. Here is the actual value of Pantene Industrial. We do not manufacture battery cells ourselves; instead, we specialise in the final assembly stage of the battery pack process. We also provide durable exterior, precision-fit housing and reliable assembly solutions.

We help OEM manufacturers complete their production processes with exceptional quality, ensuring that the final product is safe, robust, and ready for market.