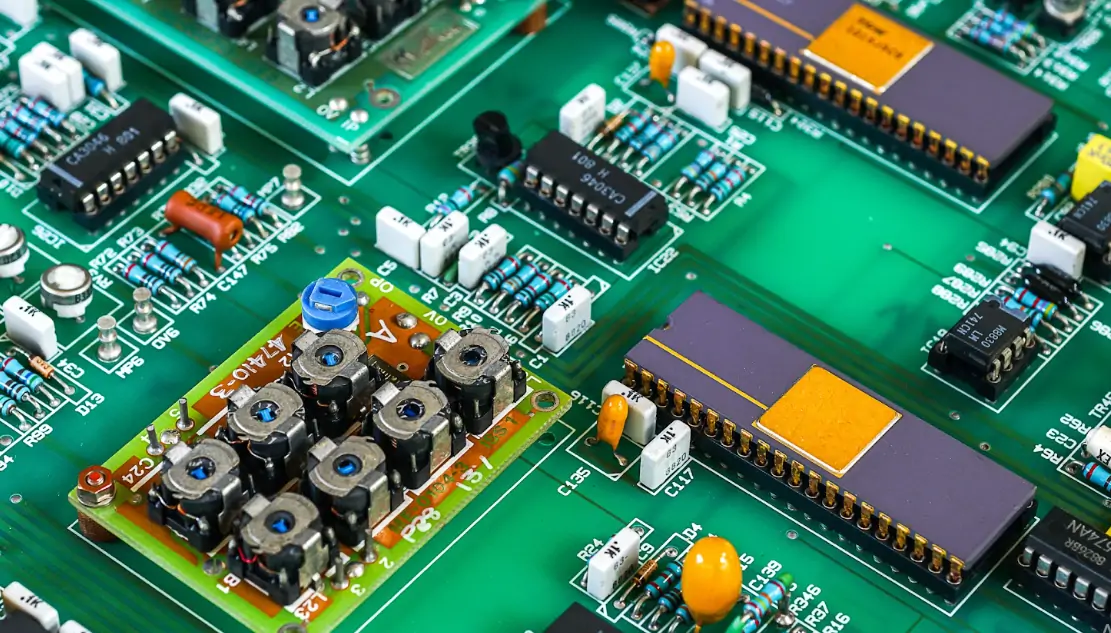

Recently, in the electronics industry, every product is designed with various types of boards to suit their target application, each with differing technical specifications. A custom PCBA (Printed Circuit Board Assembly) offers the ability to precisely meet these specifications. Different to the generic PCB that can never accommodate your design, a custom PCBA allows you to build a board that precisely matches your product dimensions, functions, and features. This article explains how we design and manufacture custom PCBA solutions based on your product vision, the steps that we follow, and why choosing a custom process gives you the optimal result for your product.

The procedure to create a custom PCBA begins with understanding your product requirements. Every project is unique; some demands require small boards with dense component placement, while other products need unusual connectors or enhanced power handling on the board, and special functions. We gather all the technical details such as:

· Board size and shape requirements.

· Types and placement of electronic components.

· Power and signal flow requirements.

· Integration with the end product casing.

· Safety certification

By collecting this information upfront, we can produce a custom PCBA that is precisely to fit your product without compromising functionality or quality. This collaborative approach ensures that the circuit board is not only part of your product but virtually a perfect match to your design.

After completing the circuit design phase, the custom PCBA design focuses on the selection of the correct components and creating a layout to ensure guaranteed performance. We choose parts based on their costs and compatibility with the operation of your device.

Our manufacturing line is designed to handle complex designs, whether your board requires:

• High-density components placement for space-restricted devices.

• Multiple layers to support complex circuits.

• Custom connectors or specialized sensors.

During assembly, we apply strict quality control to make sure that every custom PCBA is to match the specification requirement and align to the industry standard. For certain projects, the PCBA must fit precisely to the plastic housing or enclosures and, comply with the special safety standards. This collaboration ensures that the final product achieves both electrical and mechanical precision.

For products requiring low-volume manufacturing, particularly prototypes or specialized equipment, our custom PCBA service supports. For low-volume projects, we can quickly develop and revise designs to test different versions of your product.

Safety certification. We are also considering the custom PCBA reliability, for instance, in water proof, fire retardant, and so on. Our engineers select components and materials to make the board function stably under your product's specification.

Choosing a custom PCBA gives you a number of benefits over using an off-the-shelf board. Some of the key benefits are:

· Perfect fit for your product: Board is designed to accommodate your shape, size, and functional needs.

· Higher performance: Components and design are selected to allow your device's specific functions.

· Better integration: Integrate suitably with plastic casings made from the plastic injection molding process and other mechanical parts.

· Flexibility: Will accommodate both small and large volumes of production, making it ideal for prototypes and mass production.

· Cost efficiency in the long run: A board custom-made to your product minimizes redesigns and production errors.

A custom-designed PCBA can improve product quality and customer satisfaction by ensuring that all parts work as expected.

To make the process straightforward and easy to understand, here's what we do to create a custom PCBA from the ground up:

We began by discussing your product idea in detail and collecting all technical specifications., including board size, required functionality, power requirement, and environmental operating conditions. With this information, we create a detail plan covering project cost, timeline, and the best delivery schedule for you. Procuring accurate data at this stage ensures the custom PCBA is compatible with your product and reliable in its intended application.

Our designers create a detailed circuit design and PCB layout based on your specifications. We carefully optimize component placement, signal routing, and layer design to ensure everything works as it should. Our goal is to deliver a custom PCBA that seamlessly fits your product size and functional requriements.

We carefully choose electronic components that suit your board's intended function and purpose. It entails balancing the quality, cost, and availability without compromising compatibility with the circuit design. Proper selection of components ensures your custom PCBA runs optimally and sustains long-term production viable without compromising durability or performance.

A prototype custom PCBA is manufactured to test the design under real life. This stage offers all function, fit, and electrical performance testing before mass production. Changes are made here if necessary to offer the end product with consistent quality and dependable performance.

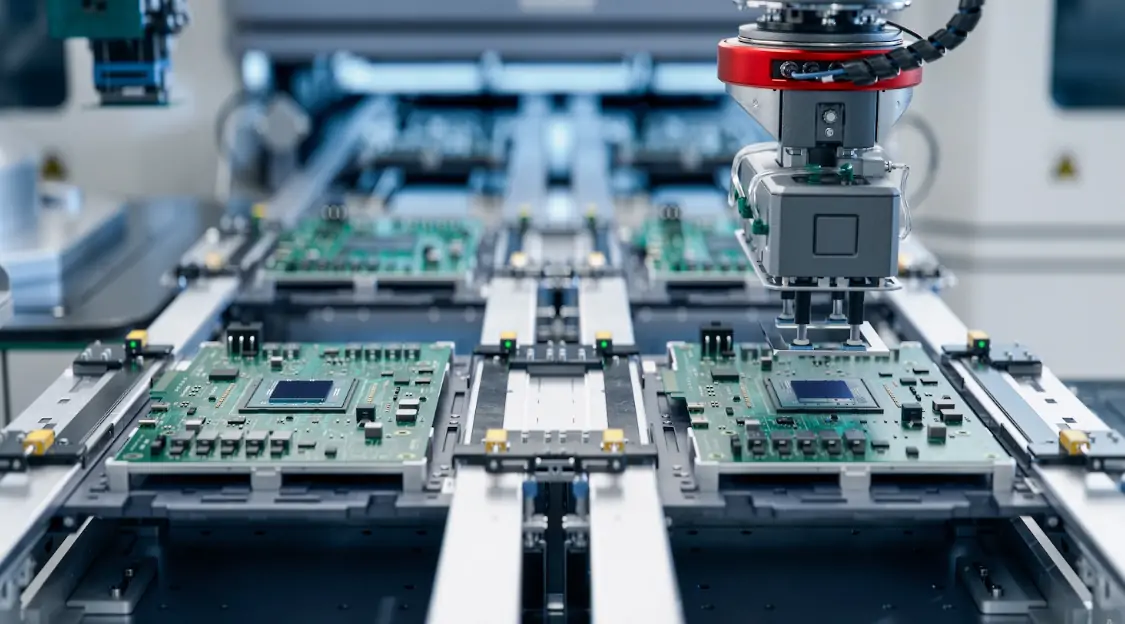

Once the prototype has passed testing and received approval, we move forward with mass production. Each custom PCBA is manufactured under strict quality control to ensure consistency. Our process ensures that every board complies with customer’s specifications, making the final product ready for seamless integration into your device without malfunction or delay.

Completed boards are implemented and validated on actual product assembly. We ensure proper alignment, electrical contact, and fit in mechanical enclosures, like injection-molded plastic parts. It ensures the customer-specific PCBA ideally interfaces with the device design and provides seamless functionality after product completion.

PI’s strict quality management system covers every stage of the process—from incoming materials, warehouse to production and final products. Comprehensive verification tests are conducted in our QC lab, using equipments such as RoHS testers, salt spray test chambers, high and low-temperature chambers, vibration tester, drop test equipment and more. For example, X-RAY inspection equipment is used to verify the quality of BGA soldering during the SMT process.

Why Choose Pantene Industrial for Your Custom PCBA

We have many years of expertise in creating reliable custom PCBA solutions for our customers including speed controller to the high power battery charger. Our team focuses on:

· Close communication with your engineering team.

· Streamlined and efficient assembly processes.

· Coordination with mechanical design teams for perfect product integration.

· Adaptability to support both small scale and large scale production.

Whether you are launching a new product or refining an existing one, our custom PCBA service provides the accuracy to turn your concept into your goals.

A custom PCBA enables us to design circuit board assemblies to your product vision. From circuit design and components selection to integration into housings produced via plastic injection molding process, we ensure every step meets your requirements. Emphasizing close collaboration, flexible manufacturing, and accurate assembly, we deliver customized PCBA solutions that enhance performance and reliability. Whether you require testing in small batches or full production runs, our process is tailored to produce circuit boards built and designed exactly to your specifications.