PCBA manufacturing is a crucial part of today's electronics manufacturing. From smartphones to industrial machinery, every device depends on high quality PCBA printed circuit board assemblies. The manufacturing process involves several critical stages, including solder paste, component injection, soldering inspection, and functional testing. Each step is carefully controlled to ensure the finished boards meet strict quality standards. A successful PCBA manufacturing process delivers precision, reliability, and cost efficiency, ensuring product performance. In this article, we explore the comprehensive PCBA manufacturing process, the key technologies, and the importance of accuracy at every stage in producing high quality products.

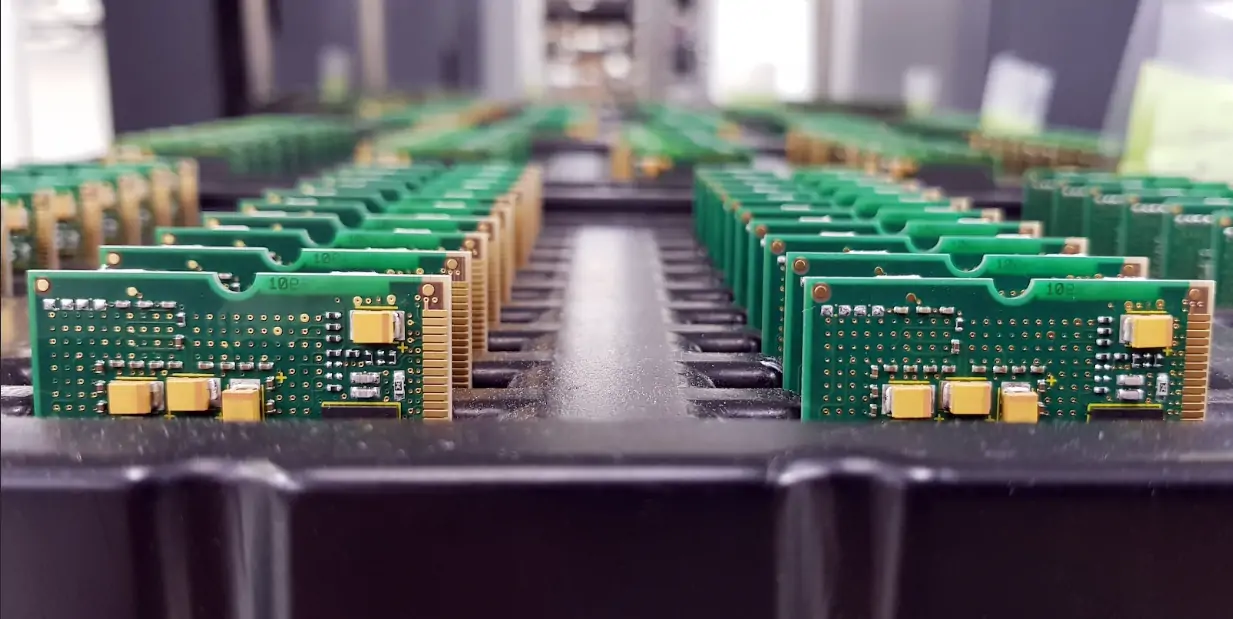

This is involved recognizing the step by step assembly of electronic components onto bare printed circuit board to create fully functional assemblies. It begins with precise solder paste, surface mount technology components insertion, soldering, inspection and 100% testing to ensure each board meets strict quality standards. A reliable PCBA manufacturing process emphasizes precision, reliability, and cost-effectiveness with minimal defects.

After receiving the bare PCB, it is first loaded onto a solder paste printing machine, which accurately applies solder paste to specific locations on the surfac,e mapping to each component pad.

· Solder Paste Printing: The operation begins by applying accurate solder paste to the pads on the board. Accurate paste volume reduces defects and ensures strong solder joints.

· Pick and Place: The components are loaded onto the board by high-speed machines with high accuracy. Real-time monitoring helps prevent misplacement.

· Reflow Soldering: The board is passed through a temperature-controlled oven with different zone of heating where the solder paste gets melted and soldered, creating rigid electrical connection. Temperature control and wetting time are equally crucial in obtaining solder quality of industrial standards.

· AOI : The board undergoes automatic optical inspection to ensure all components are correct and in position, sufficiently soldered, and that components are correctly positioned without any tinting or other damage

SMT enables high-density packaging and support high-volume production, making it essential in modern electronics. Combined with specialized PCBA design, SMT accommodates unique component requirements and layouts.

Not all of the components can be mounted SMT. Some require through-hole assembly, where component leads pass through holes and insert into the PCB and are soldered on the opposite side.

· Selective Soldering: Selective soldering machines apply solder only in the pins that are needed for specific areas.

· Wave Soldering: Mass production put the board through wave soldering machine to get multiple components simultaneously.

· Manual Touch Up: Highly skilled technicians perform touch-up and alignment where automated tools are unable to reach.

Through-hole assembly provides robust mechanical connections and is needed for components, high power support, making it ideal for the high power design products.

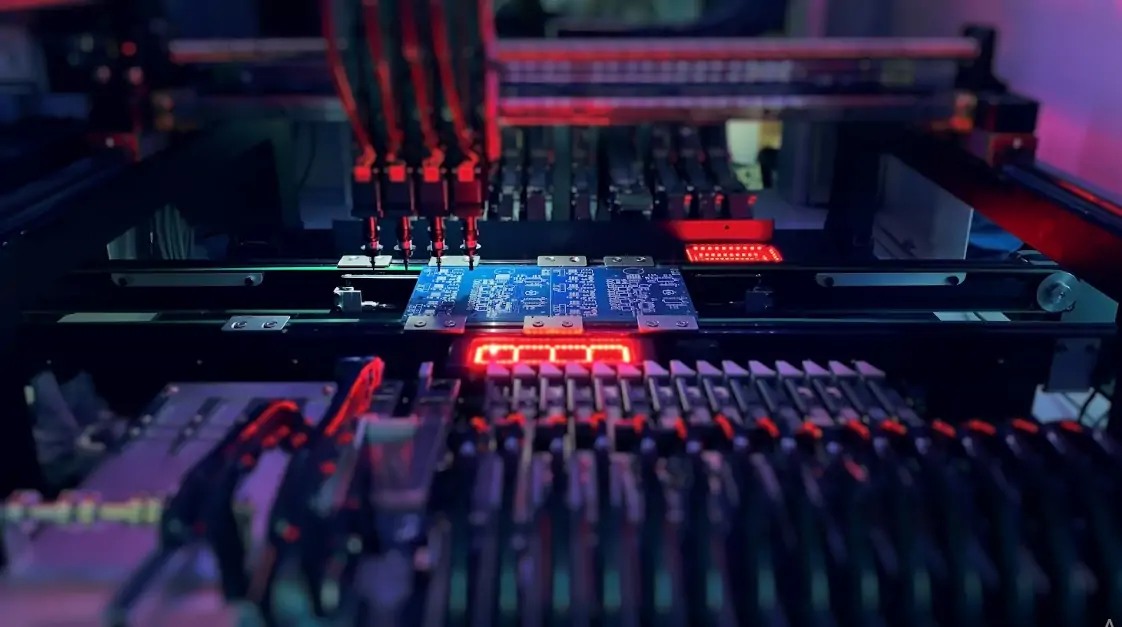

Inspection is essential to ensure each assembly is meeting quality standards. Inline Automated Optical Inspection (AOI) machines are the standard in modern SMT line factories to inspect the solder joints and component placement automatically.

· AOI Inspection: Captures high-definition images and compares the image to the design for checking misplacement, missing parts, or solder defects.

· X-ray Inspection: For more detail on solder joints, such as Ball Grid Array (BGA) components or detailed bonding wire inspection.

AOI provides instantaneous feedback, allowing the engineers to address process issues immediately. This stage in PCBA production minimizes errors and provides consistent quality in bulk production.

Testing is the final step before the PCBA is qualified for use. Testing ensures the product functions under different conditions as anticipated.

· In-Circuit Testing (ICT): Checks individual components for proper installation and functionality.

· Functional Testing/ATE: simulates real conditions to validate overall board functionality.

· Burn-In Testing: Placing the board under prolonged stress to uncover possible faults before shipping.

Adding thorough testing, companies can guarantee reliable products for end-users. To companies seeking one-stop solutions, incorporating testing in the same facility reduces the likelihood of defects and optimizes delivery times.

Selecting a supplier that offers one-stop solutions is cost-effective, time-efficient, and well-organized the project follow-up. We handle all aspects, from PCB design and final assembly to purchasing injection-molded plastic components and final testing.

Advantages are:

· The quality in all the stages is consistent.

· Faster turnaround with in-house coordination.

· Lower production costs with bundled services.

Engaging one company for custom PCBA designs helps businesses avoid miscommunication and compatibility problems that often arise when coordinating several vendors for specialized needs

Many electronic devices are not completed with the PCB assembly; they also require sturdy enclosures or structural support. Injected plastic parts are quite often used to enclose PCBA, protect components, and provide mechanical strength.

Manufacturers with in-house capability for PCBA and plastic parts production can integrate these processes, ensuring a precise fit between the board and its enclosure. This integration reduces rework and assembly time, lowers overall cost, and improves product consistency.

The PCBA manufacturing process is a rigorous workflow that integrates precision, advanced technology, and stringent quality control. From SMT, through-hole assembly to inspection and final testing, each step has a critical role in producing reliable electronic products.

Partnering with a supplier that offers one-stop services can simplify the process by taking care of every aspect from design and assembly to making injection molded plastic parts. For businesses with specific requirements, customized PCBA solutions ensure that the final product meets exact specifications and has long-term performance. By focusing on accurate solder paste control , precise SMT, managed reflow soldering, automated testing, and strict testing, manufacturers can produce high-quality boards to the market.