Solenoid coil design plays a crucial role in many electrical and mechanical applications. Whether you’re working on a simple actuator or a complex automation system, understanding how to select the right wire, insulation, and overmolding materials can significantly impact the coil's efficiency, durability, and overall performance. In this article, we will discuss how to choose suitable magnet wire and insulation, select the proper overmolding material, and validate your solenoid coil production to ensure it meets the required standards.

Choosing the right wire and insulation material is one of the most important steps in solenoid coil design. The insulated wire you use needs to conduct electricity efficiently, handle the required current without overheating, and fit within the mechanical constraints of the design.

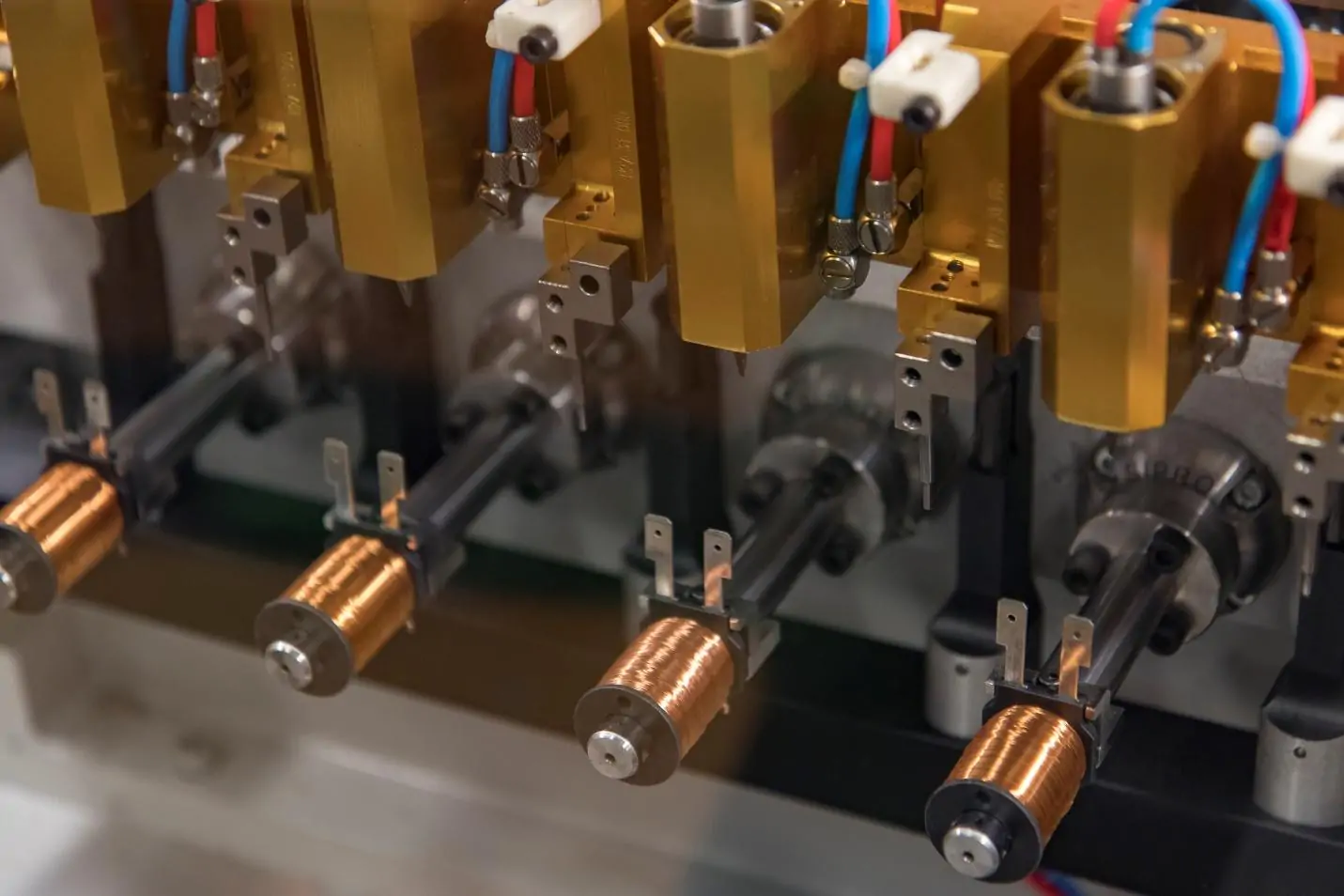

The insulated wire is typically copper or aluminum wire coated with a thin layer of insulation. Copper wire is preferred due to its excellent electrical conductivity and durability. When selecting wire gauge, consider the current your solenoid coil will carry; a thicker wire has less resistance and can handle more current but takes up more space. A thinner wire allows for more turns of wire in the coil but increases resistance and heat generation. For most solenoid coil design projects, copper wire with enamel insulation is common because it offers a good balance of conductivity and insulation thickness.

Insulation material is critical for preventing electrical shorts between coil windings. It must withstand voltage, mechanical stress, and temperature. The most commonly used insulation types in solenoid coil design are:

When deciding on insulation, always check the operating temperature and electrical requirements of your solenoid coil design. Using the wrong insulation can lead to premature coil failure.

Overmolding is the process of covering the solenoid coil with a protective layer that provides mechanical protection, electrical insulation, and environmental resistance. The choice of overmolding material depends largely on where and how the solenoid coil will be used.

Overmolding plays a vital role in protecting solenoid coils from mechanical stress, moisture, chemicals, and high temperatures. Below are the most commonly used materials, including those preferred for high-performance industrial (PI) applications:

Widely used in PI solenoid coils, PET offers exceptional thermal and chemical resistance, making it ideal for harsh environments like automotive transmissions and fuel systems. With a heat deflection temperature of up to 155°C and low moisture absorption, PET ensures long-term durability and electrical stability, especially in high-load and high-temperature applications.

Another top choice for higher temperature overmolding, LCP excels in high-precision solenoid designs due to its ultra-high flow properties and dimensional stability. Withstanding temperatures up to 260°C, it’s ideal for miniature solenoids and medical or aerospace-grade components where thin-wall molding and accuracy are essential.

Epoxy provides rigid encapsulation with excellent mechanical strength, electrical insulation, and chemical resistance. It’s a preferred choice for potting industrial-grade coils, especially those exposed to demanding mechanical loads and high operating temperatures in aerospace and heavy manufacturing environments.

Reinforced PBT enhances structural stiffness, thermal performance, and vibration resistance. It’s commonly used in industrial solenoids operating in dynamic environments, where moderate cost, flame retardancy, and strong dielectric properties are required.

TPE offers rubber-like flexibility and is frequently used for solenoids in consumer appliances and handheld tools. It provides a moisture-tight seal and shock absorption but is generally not suited for extreme temperatures or aggressive chemicals.

When selecting an overmolding material, consider factors like mechanical stress, moisture exposure, temperature range, and chemical resistance. For example, a solenoid coil used in automotive or outdoor applications will require a different overmolding material than one used in a controlled factory environment.

If you are new to solenoid coil design, it’s helpful to understand how solenoid coils work. A solenoid coil creates a magnetic field when electric current passes through its windings. This magnetic field moves a metal core or plunger, converting electrical energy into mechanical motion. The strength and speed of this movement depend on factors like coil design, wire gauge, and current. In many projects, knowing how solenoid coil works helps optimize your design for the intended application, whether it’s in valves, relays, or locking mechanisms.

Different types of solenoid coil designs exist, each suited for specific applications. Some common types include:

Knowing the types of solenoid coil available will help you make informed choices in your design process.

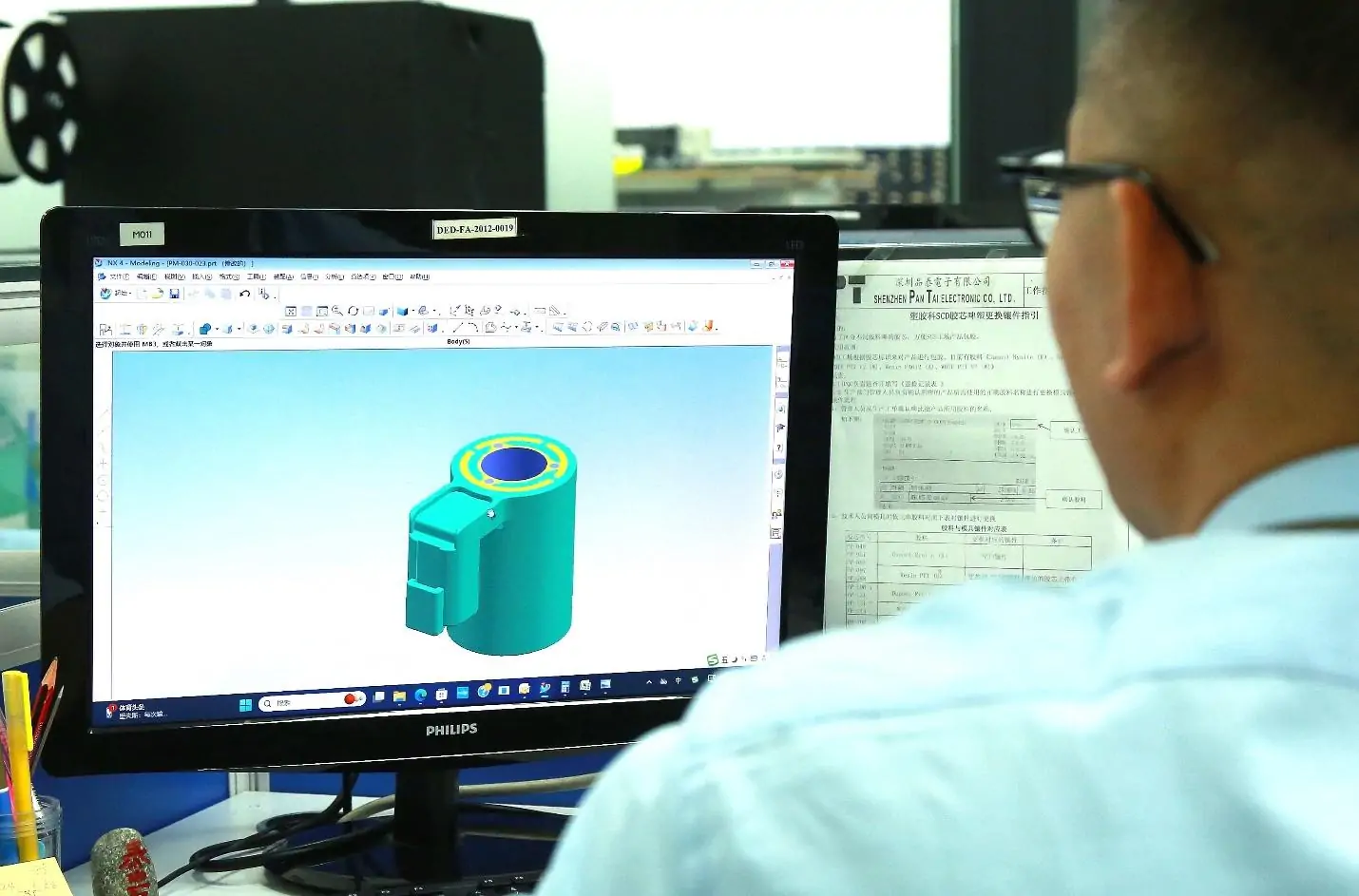

When it comes to solenoid coil manufacturing, partnering with experts can save time and avoid costly mistakes. As Pantene Industrial owns deep manufacturing experience of hydraulic solenoid coil market, with decades experience, Pantene Industrial team provides comprehensive support to make the customer’s design perfectly implement, ensuring solenoid coil meets exact performance and quality standards.