Solenoid coils are key parts of modern automation systems. They work by converting electrical energy into mechanical motion, allowing machines to operate with better control and accuracy. There are several types of solenoid coil, each designed for specific functions such as switching, controlling fluid flow, or creating linear or rotary motion. Knowing how each type works and where it fits best helps engineers and technicians make smart decisions when building or upgrading systems. Choosing the right solenoid coil can improve safety, performance, and reliability in automated processes across industries. Solenoid coils are truly vital in today’s automated world.

A solenoid coil is a tightly wound wire, usually copper or aluminum, that creates a magnetic field when an electric current passes through it. This magnetic field can move a ferromagnetic core or plunger, enabling mechanical actions like opening or closing valves, actuating switches, or controlling fluid flow.

Solenoid coils are electromagnetic components designed to convert electrical energy into mechanical movement, typically either linear or rotary. Their classification depends on several factors including motion type, power source (AC or DC), core structure, and application. Understanding the different types is essential for engineers to ensure optimal performance and compatibility in automation systems. Below are five major types of solenoid coils categorized based on their design and functional characteristics.

Classification Basis: Power Source (AC), Core Structure (Laminated Core)

AC laminated solenoids operate on alternating current and feature a laminated metal core—layers of thin metal stacked together—to reduce eddy current losses and heat buildup. This design enhances magnetic efficiency and allows for quick actuation. They are ideal for high-speed applications such as electrical relays, power circuit breakers, and other switching devices. If your system relies on fast response under AC power, this type is often the preferred choice.

Classification Basis: Power Source (DC), Core Structure (C-Frame Design)

DC C-frame solenoids are powered by direct current and designed with a C-shaped metal frame that enhances the focus and strength of the magnetic field. This type is known for its stable and quiet operation, avoiding the humming commonly associated with AC solenoids. They are widely used in automotive assemblies, vending machines, and industrial actuators—where reliability and steady force output are crucial. Their open-frame design also allows for easier installation and maintenance.

Classification Basis: Motion Type (Linear)

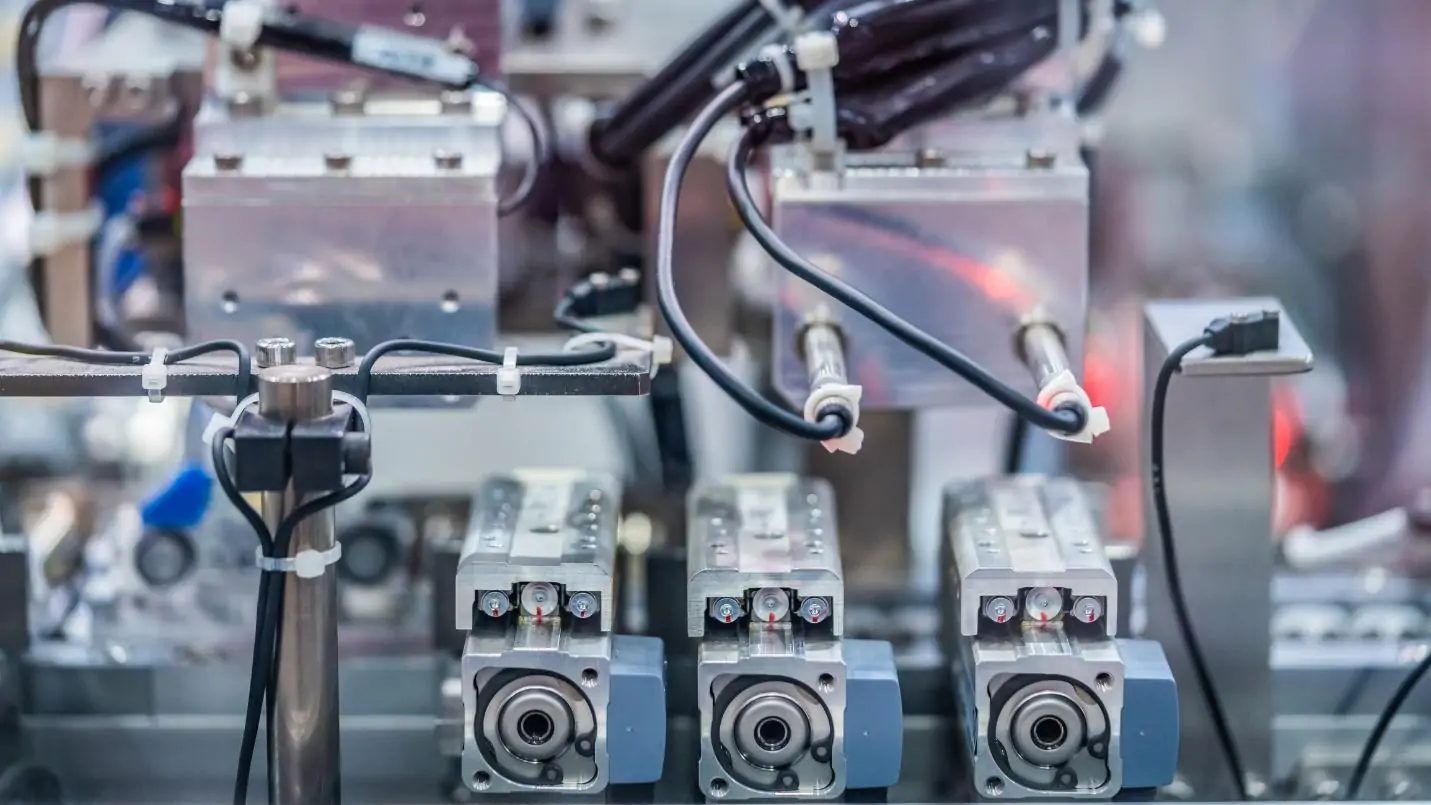

Linear solenoids produce straight-line (axial) movement, either push-type or pull-type, based on the valve design. When energized, they generate a magnetic field that moves a plunger or rod inward or outward. These solenoids are commonly used in electronic door locks, fuel injectors, medical pumps, and vending machines. Their precise linear actuation makes them ideal for applications requiring controlled, on-demand motion.

Classification Basis: Motion Type (Rotary)

Rotary solenoids differ from linear types by producing rotational movement. They use helical grooves or ball-bearing mechanisms to convert magnetic force into angular motion—typically between 30° and 90°. These are used in devices like camera shutters, coin mechanisms, and gaming equipment where a brief, precise rotation is needed. Their compact and durable design makes them well-suited for repetitive mechanical tasks requiring rotational actuation.

Classification Basis: Function/Application (Variable Flow/Pressure Control)

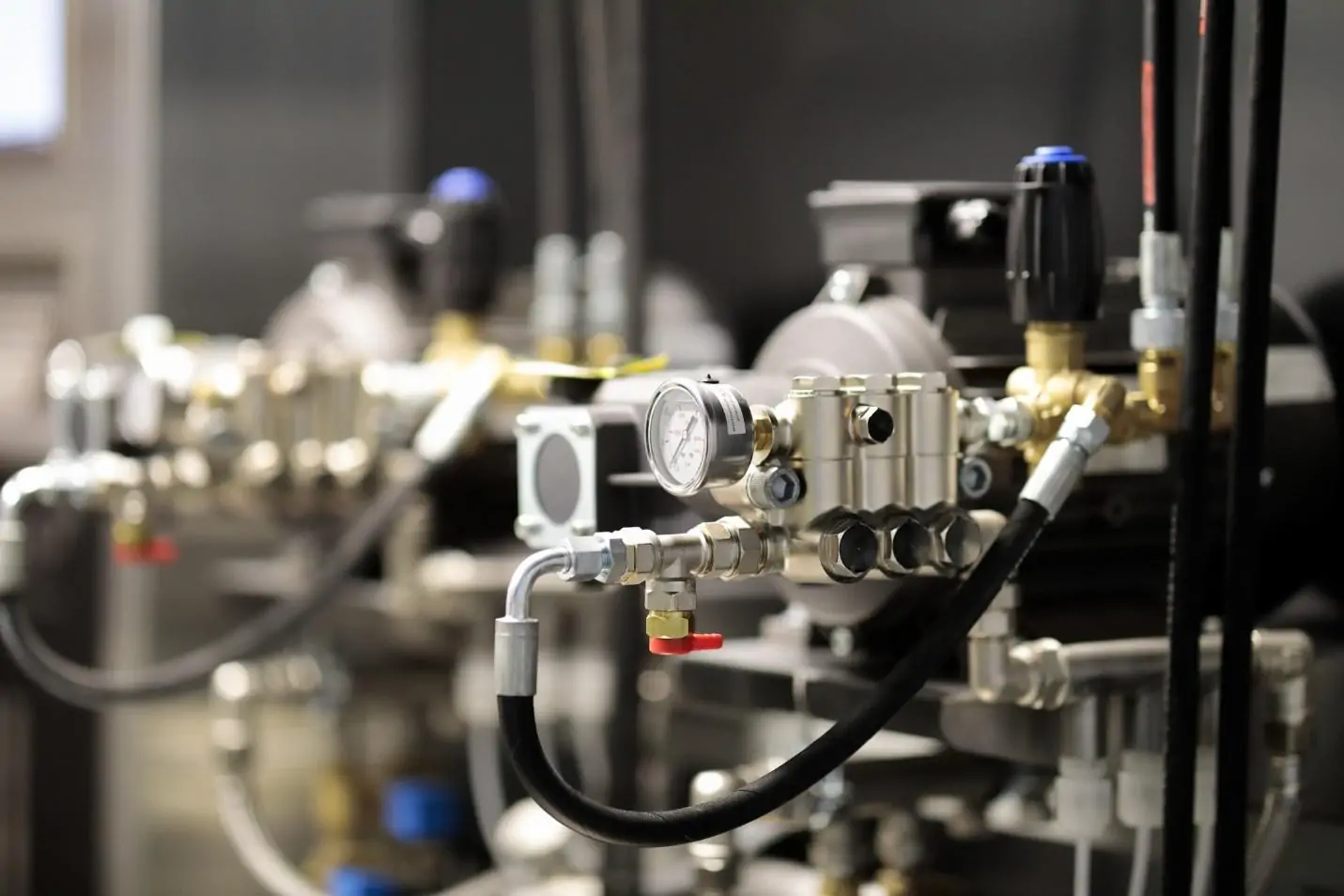

Proportional solenoids are designed for applications that demand variable control rather than simple on/off operation. They adjust the position of the plunger or spool in proportion to the electrical input, allowing smooth modulation of flow rate or pressure. Commonly used in hydraulic and pneumatic systems, these solenoids act as control valves in automotive, manufacturing, and process industries. Their high precision makes them essential in systems where performance needs to be continuously adjusted.

How solenoid coil works? When an electric current flows through a solenoid coil, it generates a magnetic field. This magnetic field can move a ferromagnetic core or plunger, converting electrical energy into mechanical motion. The direction and strength of the magnetic field depend on the current's direction and magnitude, allowing for precise control of the mechanical movement.

Solenoid coils play a pivotal role in various automation systems, enhancing industrial performance through precise control and reliability.

Solenoid valves, which utilize solenoid coils, are integral in controlling the flow of fluids in systems like HVAC, irrigation, and industrial machinery. They can shut off, release, dose, distribute, or mix fluids, ensuring efficient system operation.

In manufacturing processes, solenoids are used to automate tasks such as material handling, sorting, and packaging. Their ability to provide precise linear motion makes them suitable for controlling conveyors and robotic arms, improving efficiency and reducing manual labor.

Solenoids are widely used in the automotive industry to control mechanisms like door locks, fuel injectors, and transmission systems. DC solenoids are often employed in car starter motors and other electrical systems that require high force with minimal power consumption.

In medical devices, solenoid coils are used in applications such as syringe pumps, patient monitoring systems, and drug delivery devices. Their precise linear motion is critical in applications where accuracy and reliability are paramount.

Solenoid valves are essential components in HVAC systems for controlling the flow of refrigerants, water, and air. They regulate heating and cooling systems, humidifiers, and air handlers to maintain optimal temperature and humidity levels in residential, commercial, and industrial buildings.

When selecting a solenoid coil, it’s important to match it with your specific application. Start by checking the voltage and current specifications to ensure compatibility with your power supply. Consider the response time some coils react faster than others, which can be critical for time-sensitive operations. Factor in environmental conditions such as heat, moisture, or chemical exposure, which may affect performance and durability. Finally, make sure the size and mounting style suit your system’s layout and space limitations.

In summary, Solenoid coils are essential components in automation systems, as they help convert electrical energy into mechanical motion with accuracy and speed. By understanding the different types of solenoid coil, engineers and technicians can choose the most suitable type for their specific automation tasks. Whether used to control fluid flow, activate mechanical arms, or operate safety devices, solenoid coils contribute to smoother, safer, and more efficient industrial processes. Their wide range of applications—from factory equipment to medical devices—highlights their importance. With the right selection, solenoid coils can improve system reliability and performance. Choose us for OEM solutions today.

As a professional manufacturer of Hydraulic solenoid coils, Pantene Industrial has been focusing on one-stop OEM solutions for Linear Solenoid coil over 40+ years. PI is a “go-for” partner to make the DC solenoid coil design perfectly realized!