Original Equipment Manufacturers (customers) must improve quality and bring products to market quickly through rapid mass production, all them to allocate resources to their core business. Many brands now rely on OEM partners that provide one-stop solutions. By working with a single provider that manages the entire manufacturing process, customers can simplify operations, avoid risks, and ensure consistent quality. This article explains why most famous brands choose turnkey OEM partners like us, the value of one-stop solutions, and how our company provides reliable services that customers can trust.

An OEM partner is one that deals in Electronic Manufacturing Services(EMS) for Original Equipment Manufacturers. Rather than manufacturing the printed circuit boards themselves, customers contract an expert who performs the electronic manufacturing process from beginning to end.

· Design

· Circuit Fabrication

· PCB Assembly

· Final System Assembly

· Functional Tests

· Reliability Tests

· Compliance Certification

· Packaging and Logistic Management

By having these processes outsourced, customers minimize overhead expenses and enhance efficiency. This is particularly beneficial for businesses that unleash the resource to another more valuable business.

The one-stop solution concept refers to the situation where the whole process of electronic manufacturing is done by one partner. There are various advantages this brings to customers:

|

Benefit |

How One-Stop Solutions Help customers |

|

Cost Reduction |

No need for in-house equipment, training, or extra staff. |

|

Time Savings |

Faster production cycles with integrated services. |

|

Communication Clarity |

Eliminates errors from multiple suppliers. |

|

Process Optimization |

Streamlined assembly and testing workflow. |

|

Faster Time-to-Market |

Products are delivered quickly to meet demand. |

|

Reliable Quality |

ISO9001-certified processes reduce risks. |

This combined approach is the reason why most contemporary customers prefer dealing with turnkey partners rather than handling several vendors.

Let's take PCBA product as an example.

The Electronic manufacturing process consists of several steps that need expertise and stringent quality control.

· Circuit design

· Circuit fabrication

· Procurement of components and Logistic Management

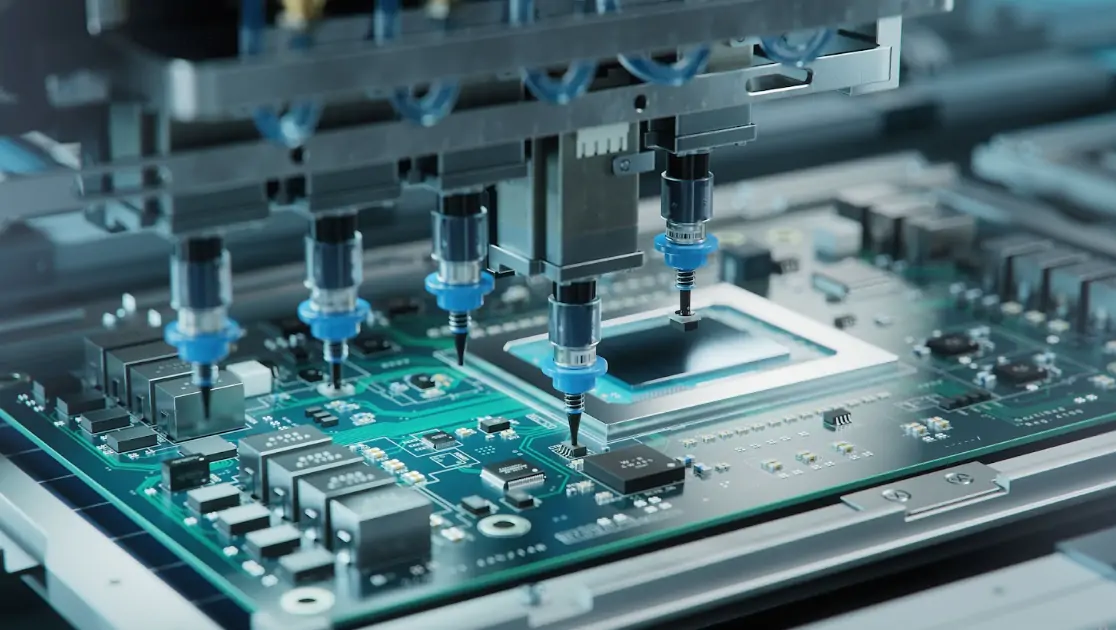

· Surface Mount Technology (SMT) assembly

· Through-hole assembly

· Soldering and inspection

· Functionality and Reliability tests

· Packaging and shipping

If a customer processes these steps with multiple suppliers for these steps, delays and quality problems often arise. By choosing a partner that offers a one-stop solution, the entire process is managed under a single system. This leads to improved traceability, fewer errors, and uniform product quality.

Customers cannot afford faulty products reaching markets. That is why it is important to select an partner with certified systems.

We work with ISO9001 certification, i.e., rigorous quality checks at each step in the Electronics manufacturing process. From the handling of BOM to final testing, documentation is meticulously taken care of to prevent errors and discrepancies.

· Systematic follow up on all the document and process flow

· Lower risk of faulty products

· Uniformity between production lots

· Accurate documentation handling

· Better trust between supplier and Customers

One of the greatest benefits of partnering with an partner is the competitive cost and short time to market savings it achieves for customers. Companies no longer have to spend capital to create in-house capabilities but can avail themselves of one-stop-shop solutions that encompass all electronic manufacturing activities. This strategy decreases financial risk, decreases project timelines, and allows customers to be more inclined toward innovation and sales than production issues.

Implementing an internal assembly line is an expensive endeavor for customers. It entails investments in specialized tools, manufacturing software, expert technicians, and maintenance. For most businesses, these investments are hard to justify when demand for their products is volatile. Through outsourcing to a one-stop shop solutions provider, customers can avoid these overheads yet still enjoy access to top-of-the-line technology, expert staff, and mature processes.

Speed is a requirement for today's electronics sector, and customers do not have room for delays. With an partner taking care of sourcing, assembly, and testing under one platform, lead time for production is reduced and streamlined. This quicker electronic production enables customers to respond rapidly to market needs, bring out their new products on time, and remain competitive in their industry. With a streamlined workflow, products go from concept to delivery in less time.

Documentation handling and management are essential when making electronics. Inadequate documentation may lead to rework, delays, or even failure to comply.

One-stop solutions from an partner ensure:

· Centralized handling of documentation

· Traceability at every stage of production

· Minimized error in component procurement and assembly and centralize procurement to optimize cost and lead time

· Engineering DFM review on prototype and new product introduction project

· Regulatory compliance

· Online quality checks during production include In-circuit test (ICT), Automatic Test Equipment(ATE), and automated optical inspection (AOI) of all populated components

This is an organized process that allows customers to have confidence in regular, risk-free production.

At Pantene Industrial (PI), we are experts at one-stop solutions that address the requirements of customers across the globe. Our hand lies in rendering full OEM services, from PCB design, circuit fabrication and parts procurement to assembly, testing, and ultimate delivery. With ISO9001-certified processes, we guarantee that each step of the manufacturing process adheres to high standards of quality. customers in consumer devices, and industrial equipment count on us for cost-effectiveness, sound delivery, and dependable performance.

· Complete PCBA OEM Services: From PCB fabrication to final assembly.

· ISO9001-Certified Quality: Reliable checks guarantee sound performance.

· Cost-Effective Operations: customers save costs by outsourcing to us.

· Streamlined PCBA manufacturing process: Shorter lead time with streamlined steps.

· Strong Customer Support: Easy communication and long-term collaboration.

By selecting PI, customers acquire a reliable partner with the ability to drive their growth and product success through documented evidence.

As electronic products become increasingly in demand, customers will increasingly rely on PCBA OEM partners that provide one-stop solutions. Compacted product cycles, rigorous quality expectations, and increasing cost pressures necessitate working with partners that ease the manufacturing process.

The trend indicates that customers will favor those suppliers who are able to:

· Render guaranteed end-to-end services

· Assure quality through certifications

· Save costs and deliver quickly

This renders turnkey PCBA OEM partners a long-term requirement for competitive customers.