Plastic injection molding is the most common process to produce precise plastic parts for applications like phones and consumer goods. The process of plastic injection allows manufacturers to produce intricate geometries with specific dimensions and high repeatability. However, product quality greatly depends on the control of the process. Small temperature, pressure, cooling, or material property fluctuations may lead to defects, low dimensional accuracy, or degraded product performance. This article explains how control of different factors during the plastic injection molding process influences product quality and why proper process management is essential in order to guarantee reliable production.

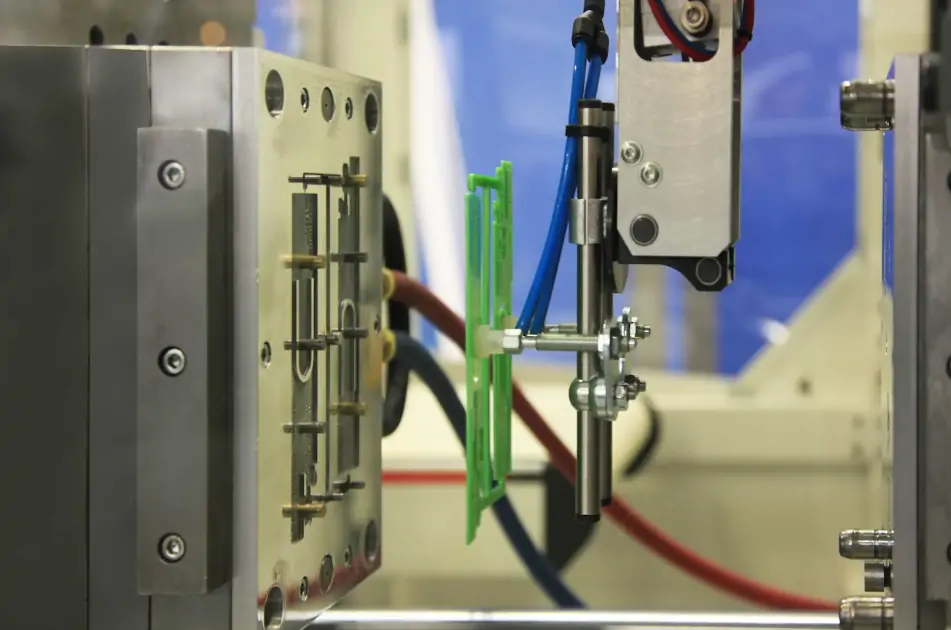

Plastic injection molding process is of a type wherein plastic material needs to be heated to melt, placed in a cavity of a mold, kept under pressure, and allowed to solidify and set in the shape desired. Any deviation at any step can lead to common defects like warping, shrinkage, sink marks, or under-filling.

Control of the process keeps:

By taking into account multiple factors at once rather than a single variable, manufacturers can provide consistency for high-volume production runs.

The following nine variables control the end product most. None of them, alone, determines quality; it is the overall control of all these factors combined that produces the optimal results.

Mold temperature influences the flow of molten plastic and solidification rate.If the mold temperature is not right, the plastic won't fill the mold fully and create short shots or poor surface finish. When the mold is too hot, it causes flash or excessive shrinkage. Mold temperature control throughout the plastic injection molding process allows even part thickness and consistent dimensions to be attained.

Injection pressure pushes the molten plastic into the mold cavity. Pressure must be neither too low nor excessive. Insufficient pressure will result in underfill, and excessive pressure will result in stress marks or flashing on the edges. The correct pressure is necessary to generate flawless parts during the procedure of plastic injection molding.

Holding time is the amount of time the plastic in molten form is subjected to pressure after injection. It allows material to pack and compensate for shrinkage upon solidification. Insufficient holding time can lead to sink marks or voids, while excessive holding could waste energy and increase cycle time.

Cooling is also a crucial plastic injection molding step. Insufficient or non-uniform cooling results in warping, stress, over or undersized errors. Proper cooling at the right time ensures even solidification and maintenance of form and internal structure of the finished part.

The temperature of the plastic material itself needs to be controlled accurately. If it is too low, the material will not fill correctly and might create weld lines or short fills. If it is more than the required temperature, the material will degrade and weaken. Well-balanced molding temperature makes the product solid and consistent.

Injection speed affects the rate at which molten plastic is filled into the mold. Low speed can potentially create weld lines or uneven surfaces, while very high speed may lead to air traps or flashing. Adjusting injection speed according to material and mold design offers even filling and quality surfaces.

The gate regulates the way the molten plastic fills the cavity. Badly designed gates will cause irregular flow, leading to defects or weak points. A perfectly designed gate fills better, reduces stress, and helps equal product thickness throughout the plastic injection molding process.

Part thickness will affect cooling, flow, and strength. Warping or sink marks result from nonuniform thickness. Part thickness is designed to be uniform to help manage shrinkage and maintain quality for high-volume production runs.

The correct selection of the plastic material play a key role in the entire process. Different resins possess different melting points, flow behavior, and shrinkage rates. Using a material that is proper and in good condition and drying it prior to use can prevent many defects and achieve consistent performance.

No single factor alone will make a good product. Instead, it is the concurrent control of mold temperature, injection pressure, cooling, material selection, and other conditions that assure the success of the plastic injection molding process. Seasoned engineers use process monitoring parameters and analysis of data to manage all these variables in equilibrium for consistent results.

In fields such as manufacturing electronics, where the components must be within certain tolerances, process control is more important. Many electronic products require plastic housings and components produced through the plastic injection molding process alongside precision metal stamping parts. Pieces of plastic and metal need to complement each other well to offer good performance.

Manufacturers that offer one-stop solutions for both plastic and metal parts can maintain tighter quality control and reduce compatibility issues. Combining one stop electronics solutions with controlled injection molding delivers high-quality products for consumer electronics and industrial devices.

Partnering with a company that provides one-stop solutions for design, tooling,plastic injection , and secondary processing helps maintain consistency. With all the stages of the plastic injection process under one system, there is better coordination between mold design, material selection, and manufacturing. It reduces communication errors, shortens lead times, and improves product quality. In addition, companies that can integrate precision metal stamping parts and plastic molding under one roof can deliver complete assemblies with reliable fit and performance. It benefits manufacturers of electronics and other high-precision items.

· Regular Parameters Measuring: It keeps the temperature, pressure, and speed settings correct.

· Prefer Material Preparation: Dry and proper handling reduce contamination and defects caused by moisture.

· Optimized Mold Design: Good mold design minimizes stress and enhances flow patterns.

· Routine Maintenance: Maintaining molds and machinery in good condition to prevent surprise defects.

The plastic injection molding process is a multifaceted process wherein various factors collaborate to product quality parts. The temperature of the mold, the injection pressure, the cooling time, the holding time, and the material characteristics all play roles in achieving precise dimensions, enhanced mechanical characteristics, and a smooth finish. For industries such as electronics, combining plastic molding with precision metal stamping parts under one-stop solutions or one stop electronics solutions provides better control and compatibility between components.By maintaining constant process control and integration of different manufacturing phases, companies can produce consistent, high-quality goods to customer specifications.