Precision metal stamping dies are essential tools in modern manufacturing. These dies produce precision metal stamping parts used in many industries like electronics, automotive, and consumer products. As technology becomes more complex and smaller, the demand for accurate and reliable components is increasing. This article explains how these dies are used, the benefits they provide, and why choosing the right partner, Pantene Industrial, is important.

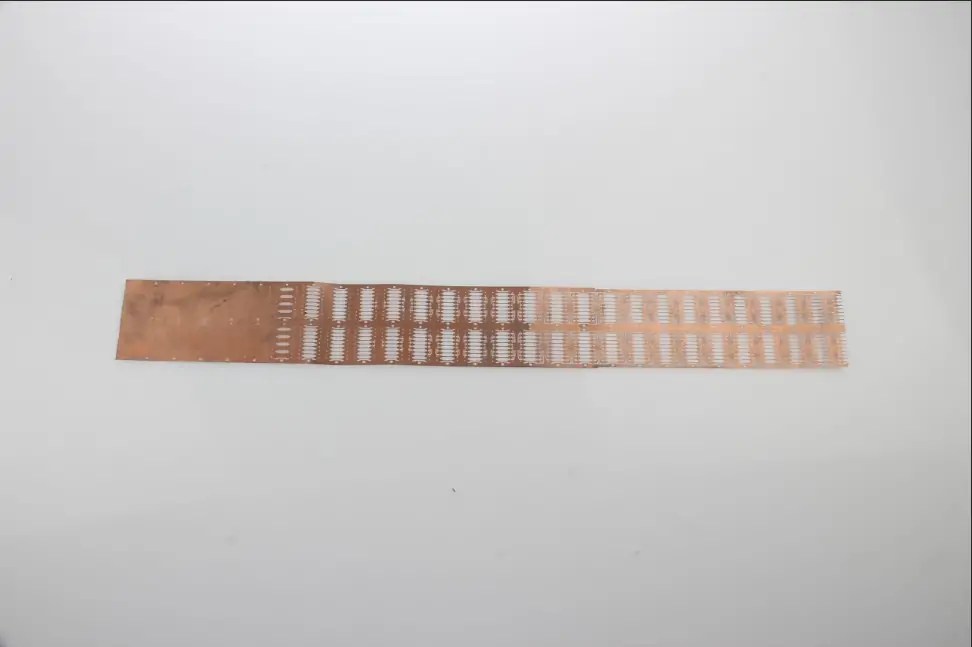

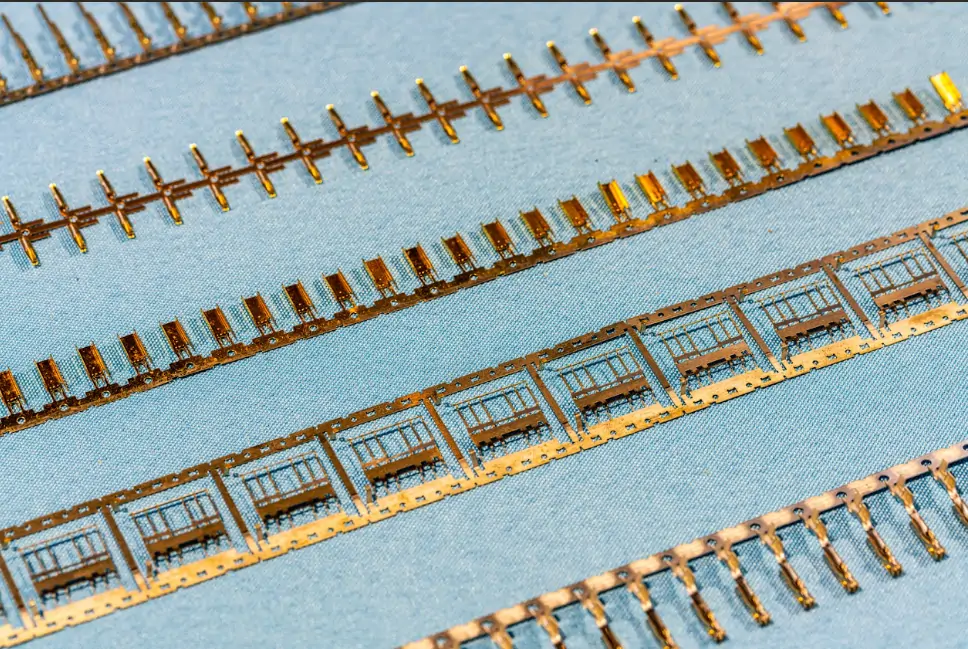

Precision metal stamping dies are tools for cutting and forming metal plates into precise shapes and sizes in the stamping process. These dies are installed in a press that stamps metal sheets to create custom shapes. The resulting precision metal stamping parts are characterized by high accuracy, consistency and mass production.

These dies are usually manufactured from tool steel and customized for specific product designs. Therefore, it plays an important role in the manufacture of parts that meet strict tolerances, especially in industries where precision is the most important.

Precision metal stamping dies are used in many industries because they can produce precise and reproducible parts. The following are key areas where these dies play an important role in the manufacture of high-quality precision metal stamping parts.

One of the most common applications of precision metal press parts is in the electronics industry. Many electronic devices require small metal components such as connectors, terminals, spring plates, and brackets. Precision metal stamping parts ensures consistent size and shape while mass producing these parts.

In the automotive industry, metal stamping or forming dies are used to manufacture body panels, brackets, engine parts, and other precision metal stamping parts. This process ensures that automakers meet the safety, design and functional standards they require.

Precision metal stamping parts are used for machines and tools used in factories and workplaces to achieve a strong and durable structure. The dies are used to manufacture gear parts, housings, brackets, shielding covers, and other metal stamping parts commonly found in electronic devices.

When choosing a manufacturing method, it is important to understand its advantages. The following are the main advantages of precision metal stamping die use, especially when mass production of high-quality and consistent precision metal stamping parts is required.

The biggest advantage of using metal stamping is high precision. Because each stamping part is almost identical, errors during assembly can be reduced. This is especially important when mass-producing for sensitive applications.

Precision metal stamping parts are cost-effective during mass production. Once a stamping die is created, thousands to millions of parts can be produced repeatedly, saving time and money in the long run.

Metal press dies can also be used for complex shapes on sheet materials that are difficult to manufacture. This makes it ideal for designing small components for electronics and high-tech devices.

Metal press machines operate at high speed and can produce large quantities of parts in a short time. This allows manufacturers to respond to severe delivery times without sacrificing quality.

In stamping processing, waste can be reduced by using only the required amount of materials. Part 4: How to Choose the Right Manufacturer for Precision Metal Stamping Parts

In manufacturing precision metal stamping parts, it is important to choose the right partner. Here are some notable points when choosing:

Reliable companies need to have high technical capabilities. Pantene Industrial focuses on embodying customer ideas and designs into real parts. With 40 years of experience in electronics manufacturing, we know how to meet strict requirements and deliver accurate results.

Pantene Industrial is dedicated to providing one-stop services to clients From design and prototyping to manufacturing and assembly, our role is to make your product vision a reality.

When choosing a manufacturer of precision metal stamping parts, it is important to check the quality control system. Pantene Industrial performs strict quality checks at all stages of production to ensure that all parts meet the specifications.

The production capacity of the manufacturer should also be considered. Pantene Industrial has facilities and human resources that can handle small to large orders without compromising quality.

A good reputation indicates that a company fulfills its promise. Pantone has developed strong relationships with clients around the world by providing high-quality metal press parts and excellent service.

Support continues after production. We support our customers by providing packing, shipping, technical support, and continuous support. This ensures that the project progresses smoothly after completion of production.

Precision metal stamping parts play an important role in the electronics industry, especially in parts such as solenoid coils and connectors. The ability to supply consistent and accurate components is essential to reliable performance in electrical and electronic applications.

Precision metal stamping parts are also widely used in solenoid coil manufacturers. These manufacturers require reliable metal frames, cases, or electrical contacts to fit their own coil designs. By using high precision metal stamping, it realizes smooth assembly and improved electrical performance.

In the production of coils, metal pressing can produce thousands of identical parts at a time. This not only improves the production speed of solenoid coil manufacturers but also contributes to cost management.

Certain metal parts are to be used as electrical contacts. These components need to conduct electricity, withstand heat, and withstand corrosion efficiently.

Part 6: Why Pantene Industrial Is the Right Choice for You

Precision metal stamping parts from reliable companies affect the quality and reliability of final products. Pantene Industrial is one of the leading partners in custom metal parts manufacturing, especially in the electronics sector. Pantene Industrial is not just a supplier but your complete manufacturing partner. We have been helping customers make their electronic product ideas a reality for over 40 years. We specialize in OEM/ODM services utilizing our abundant experience in electronic equipment assembly, component design, and high-quality manufacturing.

Precision metal stamping parts play an indispensable role in the manufacture of small, accurate, and reliable parts in various industries, from electronics to the automotive industry. By using high-quality dies, performance improvement, cost reduction, and productivity improvement are realized. If you are looking for a reliable metal stamping service or a solenoid coil manufacturer, you can partner with an experienced provider like Pantene Industrial to provide the right parts for you. Utilizing our technical capabilities, full-service capabilities, and commitment to quality, we are ready to support your next project.