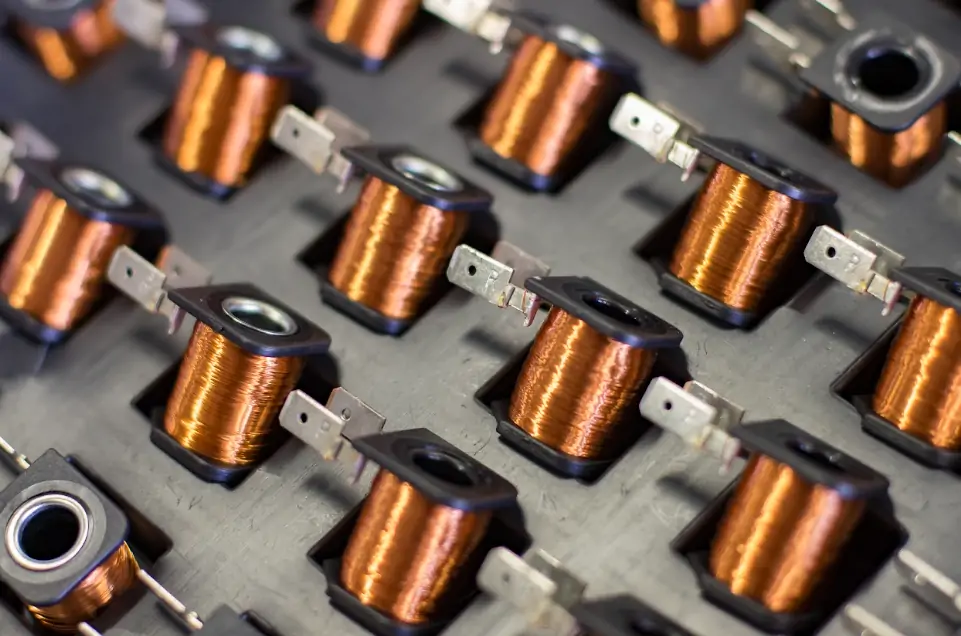

When sourcing components for your devices or systems, working with dependable solenoid coil manufacturers is essential. Solenoid coils are used in various fields such as automobiles, industrial control, home appliances, and medical technology. Without choosing the right manufacturer, product quality variations, delivery delays and additional costs may occur. In order to avoid these issues, it is important to know what points to evaluate before selecting a supplier. This guide explains the most important criteria in detailed sections and subheads to help you choose the best solenoid coil manufacturer for your business with confidence.

It is important to understand the background of a partner manufacturer before entering deep technical details. The history, expertise, and business style of the manufacturer are important indicators for determining their reliability and ability.

Companies with 40 years of experience may have worked on a variety of coil applications. These solenoid coil manufacturers understand how to adapt to customer requests and industry trends. The number of business years is a strong indicator of stability and reliability.

If you have plans to bring new products to market, make sure the manufacturer offers OEM or ODM services. These services are ideal for companies that need custom electronics and development assistance in one stop.

Check if you can share past project examples. You can determine if they are the right partner by checking what coils they manufacture and which industries they have been providing to. Actual client success stories show that they are delivering results and prove that they are not just promises.

If you are confident in the background, then evaluate their technical skills. A good manufacturer should not only manufacture the products it needs, but also have the ability to understand the technical requirements of the project.

If special shapes, voltages or materials are required, the partner must be able to provide custom solenoid coils. The ability to follow drawings, adjust designs, or improve layouts is a sign of a skilled and customer-oriented engineering team.

Manufacturers with their own engineers can quickly solve design and manufacturing problems. This reduces delays and ensures that the product meets all specifications. Especially useful for high-precision custom electronics projects.

Some manufacturers offer free or paid technical consultation before manufacturing. This avoids expensive mistakes. They also demonstrate a willingness to cooperate from the start of the project, seriously.

Customization is becoming more and more important in the current market. From professional materials to custom coil shapes, we can work with partners to deliver one-stop solutions to make your project smooth and fast.

Some manufacturers only accept large orders. On the other hand, some manufacturers can handle small orders. In the early stages, find a solenoid coil manufacturer that supports small lot production while maintaining high quality.

Companies that offer one-stop solutions consistently handle design, prototyping, testing, packing and delivery. This eliminates the need for multiple vendors to reduce errors and communication discrepancies.

Some suppliers support product development beyond manufacturing. Provide ideas for design improvements and cost savings. Especially useful when developing new custom electronic devices.

Don't forget to confirm whether the manufacturer's capabilities work as advertised by checking their facilities, employees, and workflows to understand how the manufacturer manages real manufacturing processes.

Modern winding machines, soldering tools, and automatic testing machines indicate that factories have the latest equipment and have high capabilities. These tools enable custom solenoid coils to be manufactured with higher accuracy and speed.

Check whether the manufacturer can respond to the expected quantity. Ask if you can increase your monthly production and production capacity at peak times. Production capacity is an important factor in avoiding delays.

A clean and tidy working environment indicates that the company is focused on accuracy and safety. If you have the opportunity to visit the factory (locally or online), please check these points before signing a contract.

Quality control is one of the most important factors in the manufacturing process. Lack of quality control may cause the final product to fail to function properly, even in the best design.

Make sure the manufacturer has obtained ISO 9001 and other quality certifications. These documents indicate that they follow global standards at all stages from raw material procurement to final inspection. Before shipping, the manufacturer must examine visual defects or electrical failures. A thorough final test ensures that the custom solenoid coil meets the requirements and does not cause unexpected problems.

Superior solenoid coil manufacturing companies conduct tests in multiple stages: raw materials, manufacturing processes, and final products. This multi-step approach early detects problems and guarantees high quality end products.

Professional manufacturers keep detailed records of manufacturing batches, test results and materials used. This can be useful if a problem occurs after delivery. They investigate quickly and show that they are ready to solve the problem.

A good deal is not just a price - the value matching the amount paid is important. Reliable solenoid coil manufacturers provide strong support even after the order is completed, at the right price, fast delivery time.

Check how long it takes to complete and ship your order. Please check if you can respond to an emergency order or if there is a delay. Reliable manufacturers comply with delivery time.

Strong guarantees indicate that companies are confident in their products. Please confirm the response when a quality problem occurs after delivery.

Support may be required after sales. Trusted solenoid coil manufacturers provide after-sales services such as answering questions, troubleshooting issues, and instructing on how products are used. This will save you time and make your project go smoothly.

If you're looking for reliable solenoid coil manufacturers, Pantene Industrial is a solid choice. With over 40 years of experience in OEM/ODM services, we help customers create custom electronics from start to finish. Pantene Industrial offers a complete one-stop solution, including design, prototyping, testing and delivery. Whether it's a standard coil or a fully custom solenoid coil, PI can meet your needs with technical and production capabilities while maintaining quality and consistency.

To choose reliable solenoid coil manufacturers, it is not enough to check the price. We need to comprehensively evaluate their experience, technical capabilities, customization support and commitment to quality. Make sure you have a one-stop solution and a substantial after-sales service. Pantene Industrial is a reliable partner for companies seeking custom electronics and custom solenoid coils. Their extensive experience, flexible support and commitment to quality make it the best choice for companies that want to properly complete products from concept to delivery.