Metal stamping is a common method used in many industries to produce metal parts with specific shapes and sizes. It is widely used in many areas such as custom electronic devices, automobiles, home appliances, and other industrial applications. The precision of the die used in the metal stamping process has a significant impact on the quality of the final product. This article explains how the precision of metal dies directly affects the quality of metal parts. In addition, we will examine why PI quality control processes solve common quality problems and why experienced solenoid coil manufacturers and electronics OEMs value the die accuracy.

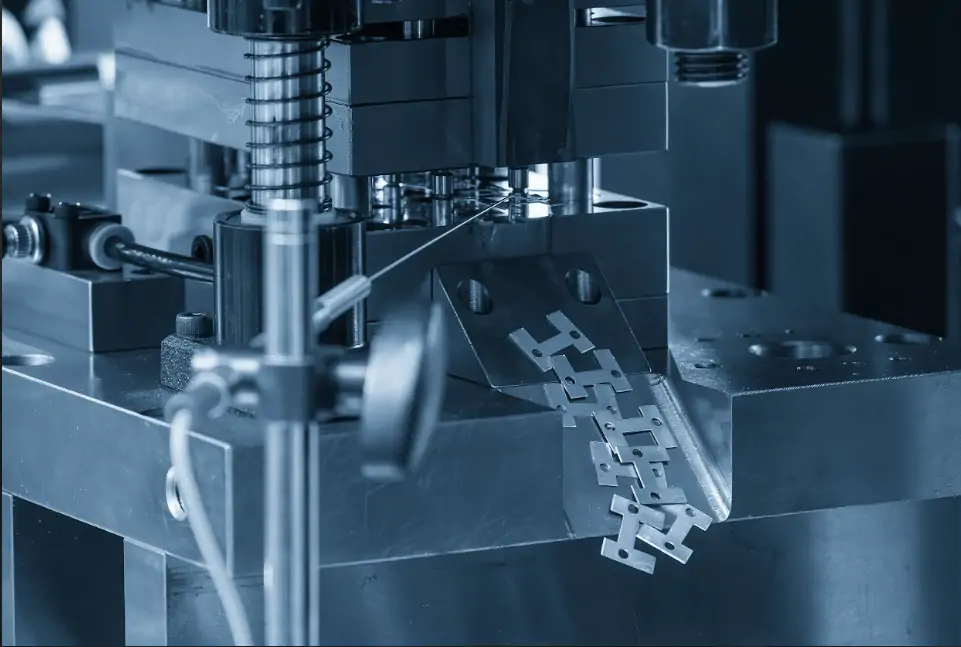

Metal stamping is not just about forming metal plates. It is a precise process that causes defective parts, even a small error in the die. Manufacturers that offer custom electronics solutions must maintain high accuracy in die manufacturing. Therefore, it is necessary to strictly control the quality of the die in the design and manufacturing stage.

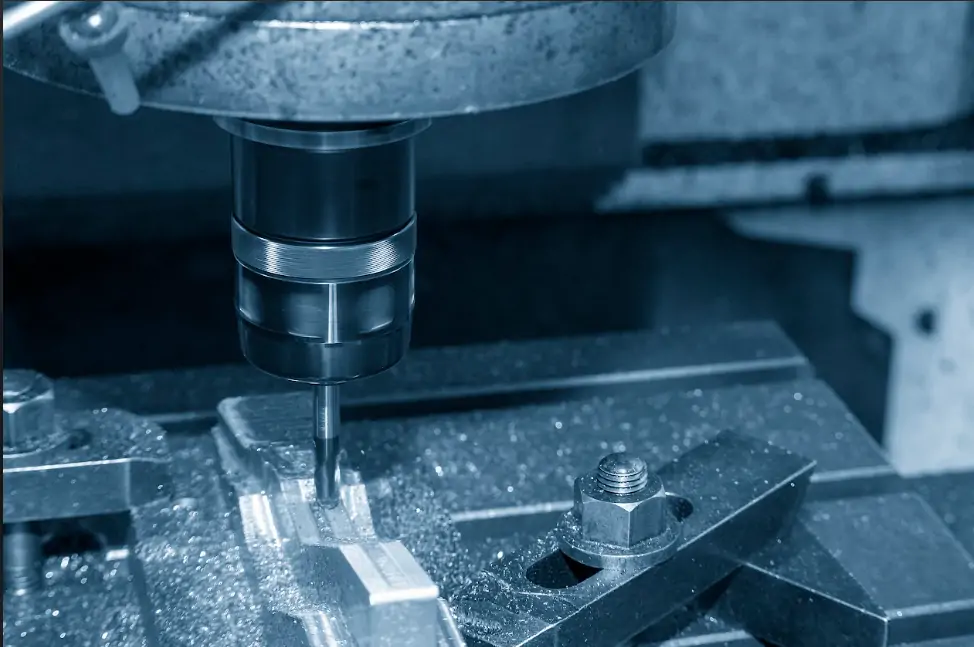

The most obvious influence of die accuracy appears in the size and shape of the metal parts to be stamped. In metal stamping processing, a stamping die is a tool that cuts metal plate into a specific shape. If the die is not manufactured correctly or worn, the part would be out of tolerance.

Proper sheet metal use for stamping of tooling materials and regular inspection are crucial. Companies that adopt quality control systems can discover material issues early and prevent major production problems.

Surface finish is another area where accuracy is affected. Coarse or poor finish die surfaces leave scratches and irregularities on metal parts.

Maintaining the surface quality of stamping dies is part of PI's quality control system. Regular polishing and inspection can prevent such defects.

If metal stamping dies are not accurate, manufacturers face many problems that slow down production and increase costs.

These problems can be mitigated by adopting reliable tooling materials, appropriate design methods, and quality control. This is especially valuable for solenoid coil manufacturers who frequently perform high-volume production with little room for error.

In the current market, companies cannot afford to supply low-quality or inconsistent quality. Customers expect reliable quality, especially in areas where small defects affect the whole, such as custom electronics.

An accurate die helps manufacturers meet customer expectations. Companies that invest in appropriate die designs and apply quality control procedures are more likely to maintain delivery time compliance and product consistency.

Pantene Industrial learned from 40 years of experience as an OEM/ODM provider that quality starts with a die. Therefore, in accordance with the PI’s quality control, all metal stamping dies manufactured have strict processes to meet the highest standards.

Through our rigorous process, we support clients in a variety of industries, including solenoid coil and custom electronics meet customers’ requirements, and provide products。

Pantene Industrial is not just a manufacturer but a reliable production partner. With over 40 years of experience in the electronics and manufacturing industries, we have built a high reputation for reliability, accuracy, and customer satisfaction. We are dedicated to a complete one-stop OEM/ODM service. We support the whole process of the project from concept development, product design, prototyping, metal stamping processing, assembly, to final delivery. Whether you're launching new products or improving existing ones, Pantene Industrial is fully equipped to make your vision a reality.

We understand how important accuracy and reliability are in the current market. Therefore, our metal stamping processing process is always thorough to realize both.

The precision of metal stamping tools has a significant impact on product quality. From shape and surface finish to strength and cost, everything depends on the quality of tool manufacturing and maintenance. Using accurate tools reduces waste, accelerates production, and ensures parts meet customer expectations. For custom electronics companies and solenoid coil manufacturers, tool accuracy is not just a technical detail but a business advantage. Pantene Industrial is committed to supporting your business with accuracy, reliability, and full-service manufacturing against the backdrop of PI quality control. Quality-critical projects require partners with decades of experience in metal stamping and end-to-end service.